I spent last Friday at the Philip Carter Winery, small winery in Hume, Virginia helping them bottle wine. A couple of times a year when the wine is ready to be bottled, they invite people who love their wine to come help them bottle it. They pay the volunteers for their help with lunch, wine, more wine, and then more (bottled) wine to take home. A friend invited me to join her with this bottling work. It sounded like a great deal to me, not to mention fun, but I didn’t realize how much I would geek out and have fun learning about the bottling operation. I learned that small wineries hire a bottling operation on wheels to come to their winery and bottle their wine when it is ready. An entire bottling operation fits on the back of medium sized truck. It is totally cool in my humble geeky opinion.

Like at all wineries, the wine is aged in barrels. It is later transferred to stainless steel vats.

Four of these vats were bottled that day. In the morning, two vats of Chardonnay were bottled, and in the afternoon two vats of Cabernet Franc were bottled. When a vat is completely empty, workers make sure all wine makes it from the vat to the bottling operation through the tubing through a highly technical process called “walking the line.” This entails people lifting the tubing up and letting gravity move the final volume of wine towards the pump. “Walking the line” also involves everyone yelling down the line “walking the line” so that the person inside the bottling truck knows the final volume of wine is coming.

Empty bottles are loaded onto a conveyor belt on the right side of the back of the truck. The people loading the empty bottles generally enjoy drinking wine while working.

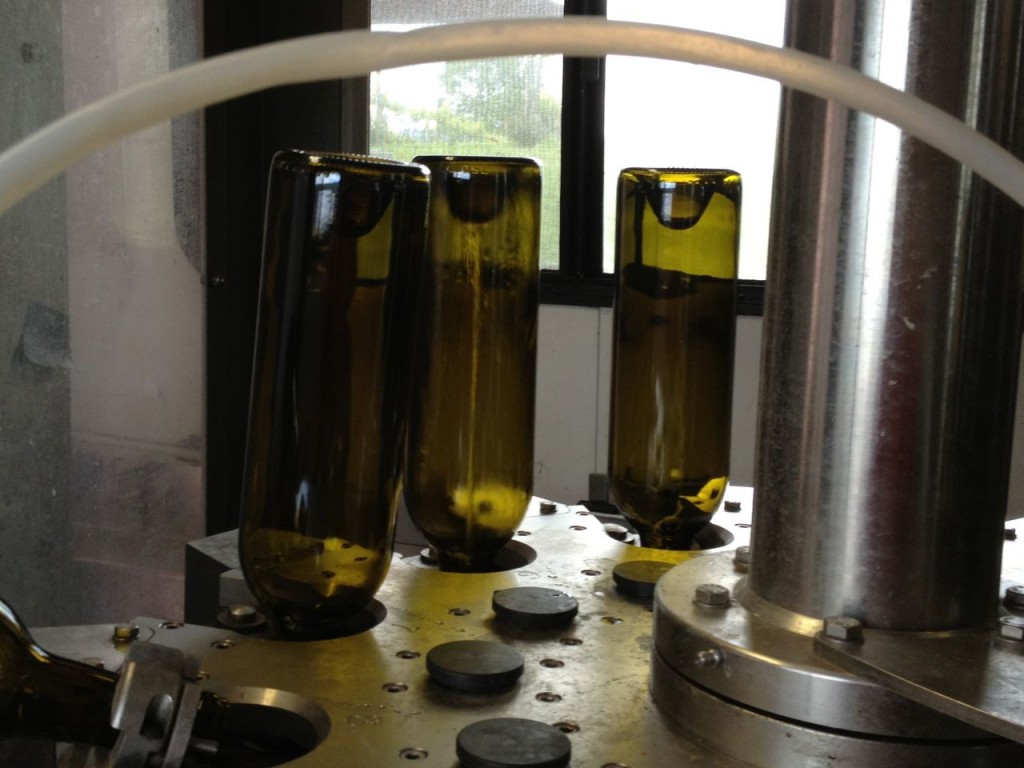

The bottles are first washed. A stream of water is squirted into the upside down bottle.

After the water drains, air is blown into the bottles to dry them. The bottles are then turned right-side up, and carbon dioxide is blown into them. Carbon dioxide is heavier than air, so carbon dioxide fills the bottle and forces air out of the bottle. This keeps the bottle free of oxygen before being filled with wine. Oxygen reacts with, or oxidizes, wine causing it to lose flavor.

The upside-down bottles on the left are being washed, and the upside-down bottles on the right are being dried by blown in air. On the far right, the right-side up bottle with the machinery attached to it, is being filled with carbon dioxide.

The bottles are then filled with wine. They are actually slightly overfilled.

A small amount of wine is then removed from the bottle to make the wine volume exactly 750 ml. Evidently it is easier to make sure the correct amount is in the bottle by overfilling then removing the extra. Then the cork is pushed into the bottle.

The bottle on the left is having the excess wine removed, and the bottle in the middle is having the cork pushed into it.

A laser then checks that the cork is in the bottle, and then the seal is placed over the bottle.

A laser (the visible red dot) checks that a cork is in the bottle in the middle, and then a seal is placed over the bottle on the right.

The seal is then pressed and stretched over the bottle to give a good seal.

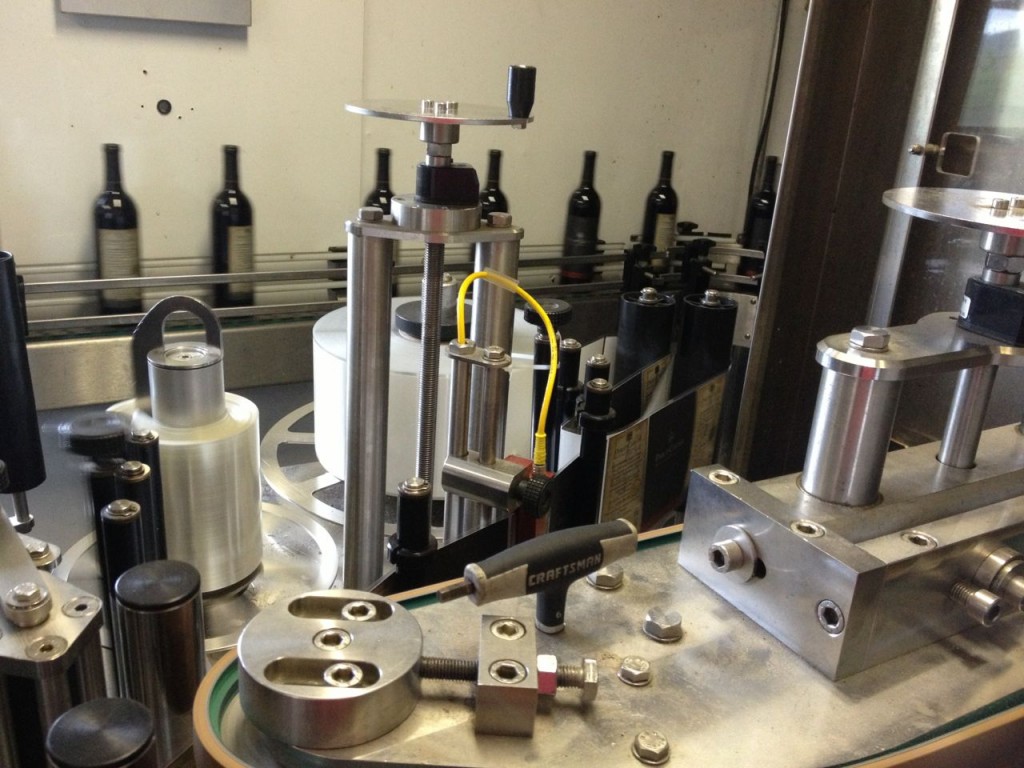

The front and back labels are then placed on the bottle. The front and back labels are on the same roll.

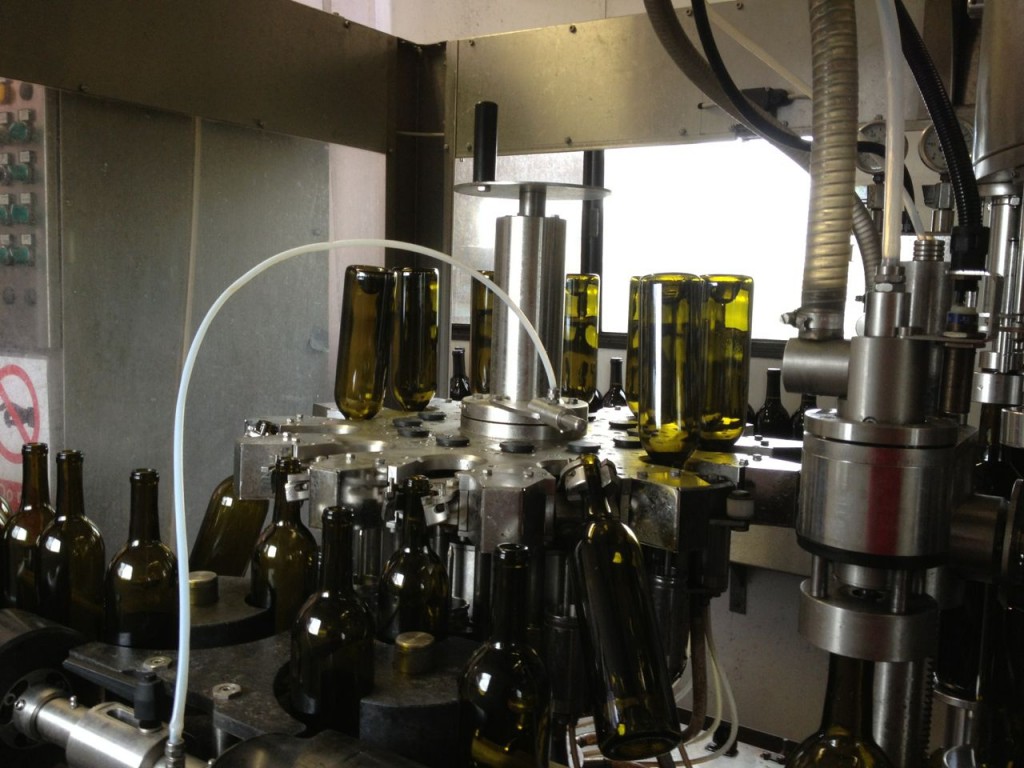

The whole bottling operation machinery is ridiculously compact.

The entire process, in the foreground is the sealer, behind it the corker, then the filler, then the washer in background

The finished bottles come out the back of the truck on the left side of the truck, five feet or so from where the empty bottles entered. They are checked by a person to make everything is perfect then put in a case.

The final product from the operation is delicious bottled wine. I want to thank the Philip Carter Winery for allowing me to help, a wonderful day, and all the delicious wine. Also, I would like to thank the operator of the bottling truck (whose name I am horribly sorry to say I don’t remember) for giving me a tour of the truck and explaining the whole process. It was great fun and incredibly interesting.