Another major milestone in my master bathroom renovation has been reach. I completely finished tiling the shower and tub area. I laid and grouted an huge amount of tile. I also tiled the ceiling above the shower because I am insane. I don’t know how many hours it took me, but it was a lot, several weekends and nights after my real job work. It looks great in my opinion, but it was a lot of work. I used two different types of tile. The vast majority of the tile is a gorgeous sea foam green marble tile called Biltmore. The main field tile is polished 2×2 inch Biltmore marble. I used various accent pieces for the edging such as the top of the top platform and a pencil around the niches. Skirting tile of the same marble is used for the baseboards of the platform and the walls. The same marble is used for the flooring, brushed 12×12 for the floor and tumbled cobble for the shower floor. I then used glass tile for accents in the niches and for the top of the tub backsplash. The glass tile is made partially from recycled glass bottles.

Category Archives: Home Renovation

Bathroom Cabinetry Installed

The master bathroom is thankfully rapidly progressing in the remodeling. I have been tiling like a mad woman, and the majority of the cabinetry has now been installed. The cabinetry consists of a vanity base, a wall cabinet next to the tub platform, and an over-the-toilet cabinet. The wall cabinet was specially designed to have a false bottom that allows access to the tub pump. Once the vanity countertop is installed there will be a shelving cabinet installed at the end. There is also crown molding and other finishing pieces that need to be installed, but the main cabinetry is installed. All cabinetry is from Tuscan Hills through Costco. I used the same style of cabinetry as my kitchen cabinets, but with a slightly different and lighter stain.

Bathroom Painted

Major milestone was reached tonight. I have completely finished painting the master bathroom and bedroom. I repainted the bedroom to match the bathroom. In the bathroom, I primed all the drywall to seal it. I then painted the areas that will not be covered with cabinetry or tile. The walls are a coral pink, and the ceiling is blue. The blue is one shade darker than the blue used one the ceilings throughout the rest of the house. I think the pink and blue will look really nice with the green tile.

Bathroom Floor Is Finished!

Sunday I grouted the bathroom floor including the shower floor, so I can officially call the floor finished. I consider that progress. I grouted those at the same time because I used sanded grout for both. The sanded grout gives more strength and flexibility that is needed on floors than an unsanded grout.

Shower Floor Tile Laid

I laid the shower floor tile on Saturday. The tile is the same marble that is used on the bathroom floor. The bathroom floor tile is 12 in x 12 in tile with a brushed finished. The tile in the shower are smaller pieces that have been tumbled into odd shapes and placed on a mesh to give a cobblestone appearance. I really like using this type of tile for a shower floor because it is naturally slip-proof and feels really good on the feet. The only problem with using this type of tile though is fitting the different pieces together. They don’t line up the way regular shaped tile does. I removed pieces from the mesh of unused tile to fill in any gaps where the tiles met or where a tile met the edge of the shower. It is a bit of extra work, but I really like the appearance and think it is worth it.

Drywall Installed

The walls are now covered. Hardibacker board covers most of the areas that will be covered with tile. Hardibacker board was used for the shower area and the backsplash of the bathtub. There will also be a tile backsplash for the vanity, but hardibacker was not necessary there. All other areas have been covered with green board. A cement base was poured in the shower.

Master Bathroom Floor Tiled

I spent the weekend tiling the master bathroom. I got off to a late start Saturday, partially due to wet saw odyssey. However, Saturday, I got all the tiled laid out and cut the majority of tile that needed to be cut. I have never used a wet saw before, so I decided to cut the tile beforehand because I wasn’t sure how it would go. I was particularly concerned about cutting the tile near the toilet supply pipe and drain pipe. Then Sunday, I cut the rest of the tile and then did the actual mortaring the tile into place. I didn’t finish until early Sunday evening. I learned quite a few things during this experience.

- Arranging and cutting the tile beforehand was a good decision. By arranging everything in advance, I was then able to make the measurements to cut the tile properly. Cutting the tile beforehand saved me critical time in laying the tile before the mortar set.

- Laying tile on top of radiant heating mats makes the task that much more difficult. It is not incredibly difficult, but a plastic trowel is essential, so the trowel doesn’t cut through the wire. A thicker layer of mortar is necessary, and getting the correct thickness is tricky. Also, it makes leveling the tile more difficult, especially when some of the tile overlays the radiant heat, but some does not.

- In my opinion, laying tile on the floor is more difficult than on the wall because you have to keep moving your location. Also it is horrible on the knees, back, and lower legs.

- As long as I worked by continuously moving back towards the door, one row at a time, I was able to keep the tile evenly spaced and in line. I started at the back of the water closet, and then worked backwards into the main bathroom. At the end I encountered an issue because after I got to the end of the tub, I needed to start at the end of the aisle that leads to the wall cabinet that will sit next to the tub. Because I kept removing two rows at a time to keep a continuous layer of mortar, I had trouble keeping these tile exactly in line with the tiles down the main aisle. There was a small discrepancy where the two areas met where the grout line will be slightly thicker than the rest of the grout lines. Hopefully no one will notice but me. Problem was the mortar had already set at the back of that small area, so I couldn’t move the tile to make it fit. In hindsight, I should have marked the wall or something, so I would have known exactly where to lay the tile in that small area.

- When the mortar directions say it has a 20-30 minute working time, it really does. You don’t get more.

- Since I laid the tile out in advance, I then had to walk across many of them while working. At least three broke while I worked. The tile is 12 x12 inch marble tile, and many have a lot of veining. Those that broke, broke on veins. While they are clearly fragile, I do not know if it they would have broken after having been set on mortar and allowed to set. Thus, was their breaking before laid, a good or bad thing?

- As stated, I am using marble tile. The tile is green, gray, and white. One of the reasons, I laid the tile in advance was so that I could lay the prettiest and greenest tile in the highest visibility areas. This was a good decision.

- Keep a small, preferably disposable, bowl with some water and a rag near you to clean up potential excess mortar that comes up between tiles when pressing down a tile to level it.

- I need a new or better, or probably both, power drill. I bought a mixer attachment for my power drill to mix the mortar. When I tried to use it, it didn’t work all that well, and the drill started smoking a little. I ended up using the trowel to do most of the mixing, especially to get the powder out of the bottom corner.

- I am not as young as I used to be, and my knees, back, and lower legs are rather upset with me at the moment.

- Ferdinand the basset hound is rather underfoot. Okay, I knew that beforehand, but he really confirmed it today.

- Ferdinand can sleep within 15 feet of an operating wet saw. No, he is not deaf as he can hear a plastic bag holding sandwich bread being opened across the house. [I always give him a piece of the bread loaf ends.]

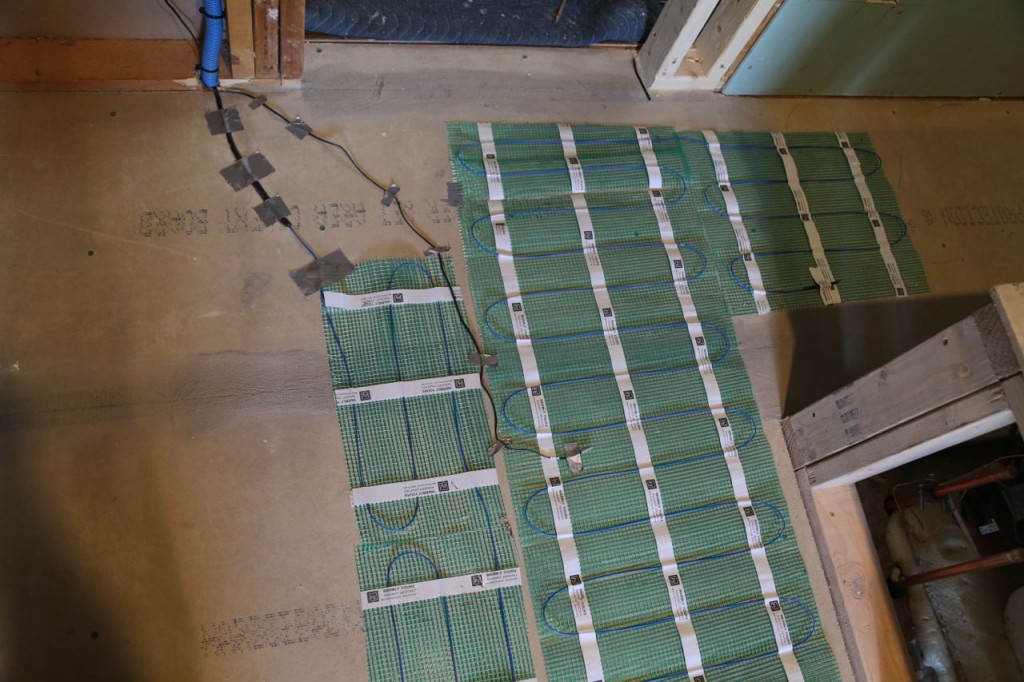

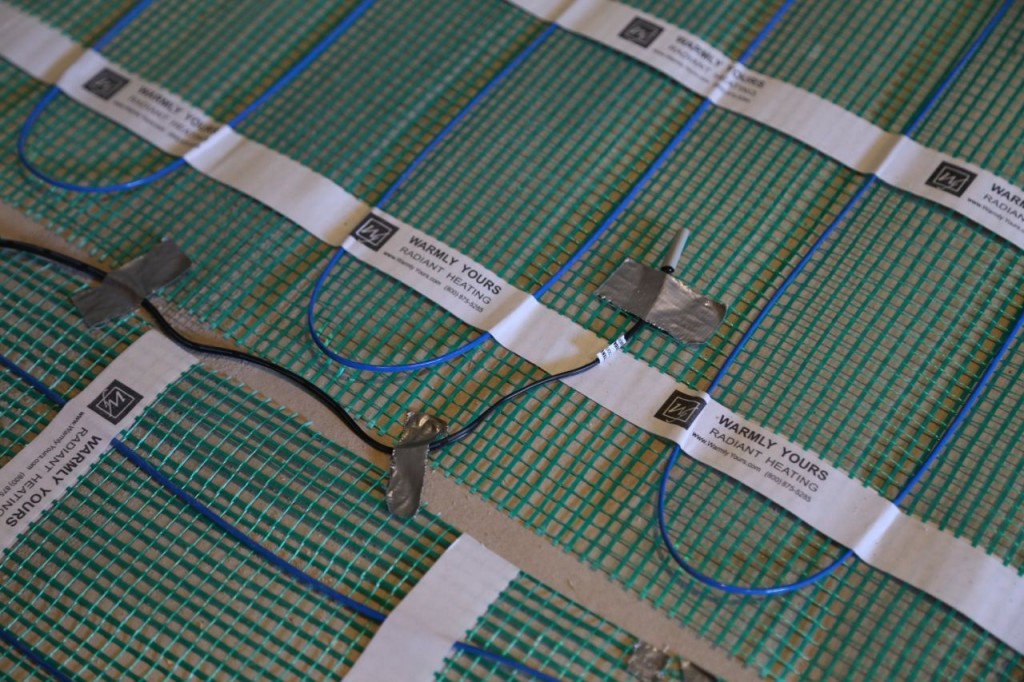

Radiant Heat Installation

After the master bathroom framing was completed, the plumber installed the bathtub and the shower liner and drain. Then I was able to install the radiant heat. The electrician then came to connect the radiant heat wiring, and then I was able to get all the concealment inspections done. I am so happy the renovation is really starting to progress. On a side note, the plumber poured water into both the bathtub and shower liner to test that neither leaked and left it in there for the inspection. While the inspector was here, Ferdinand the basset hound came in, found the water in the shower liner, and proceeded to drink said water. He then came back several times later while there was still some water left to drink. He has deemed it a fine water bowl.

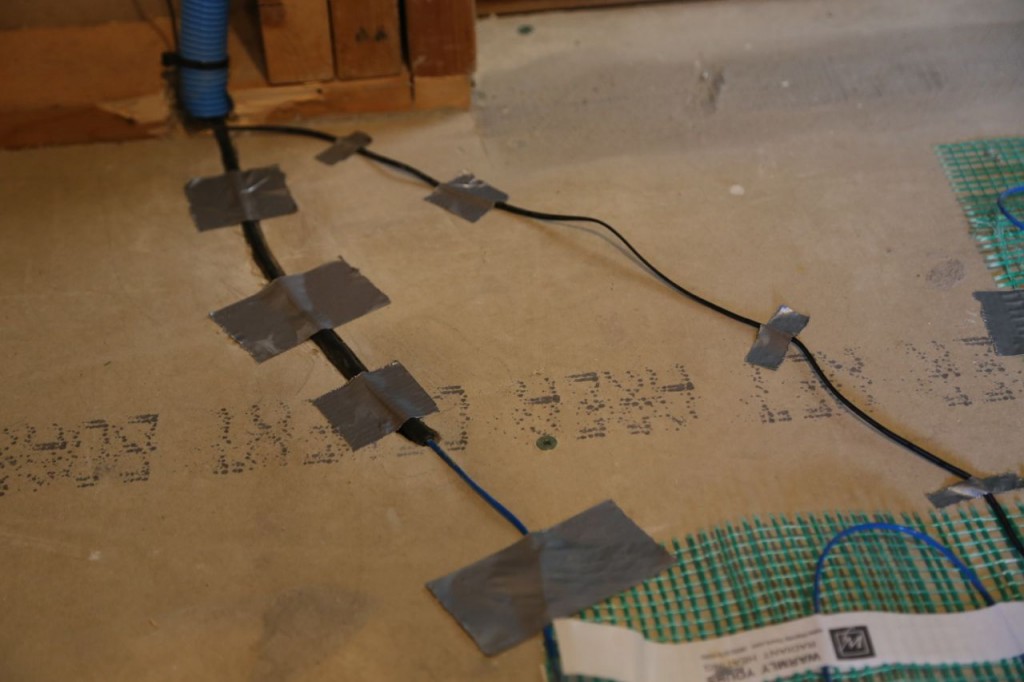

Laying the radiant heat was fairly easy. It comes in a roll, so all I had to do was unroll it and cut the mesh in places to make turns. Figuring out the turns was a bit of a geometry problem. It is only laid where a person will actually walk and not under the cabinetry. I bought a programmable thermostat for my radiant heat, so I can have it automatically heat up in the morning before I wake. It will be so nice in the winter. Because of the thermostat, there is a sensor that sits in between the electric wire to detect the temperature on the floor. It will also be covered by mortar and tile like the heating wire. One minor problem I had was that the wire that connects the radiant heat coils to the thermostat is rather thick, too thick to be buried in the mortar. I finally bored a canal of sorts for it in the Hardi backer board that serves as a subfloor. Now it lays flat, or at least does not pop up any farther than the radiant heat coils.

Master Bathroom Framing

Framing of the master bathroom is now complete. Both doors have been framed. The tub platform has been built, and the shower has been framed. I now once again have a ceiling, and drywall has been placed on some of the walls. Hardi board has been placed on the floor. Things are moving along.

Master Bathroom Reconstruction Begins

Deconstruction is finished in the master bathroom, and now the reconstruction has started. (Photos of deconstruction and reconstruction can be found on Home Renovation Phase 3.) The new pipes and values have been installed, which includes fittings for the toilet, two vanity sinks, the bathtub, a thermostatic valve for the shower, and an overhead and a hand held shower head. All the new wiring and recessed electrical fittings have also been installed, which includes recessed overhead lights over the aisle, the shower, and the bathtub, vanity lights over the sinks, and wall sconces in the toilet area. Two new exhaust fans have also been installed, one in the main bathroom area and one in the water closet area (because code required it), and the HVAVC crew have run new pipes to vent the fans to the exterior.

After the rough-ins were inspected, I installed insulation in the cavities of the exterior walls. In the shower area, this was a little difficult because of the pipes. I used foil-backed foam, which unfortunately only has an R-value of 6 behind the pipes. Between the foam behind it, and leaving the space in front of the pipes uninsulated to get heat from the bathroom interior, hopefully the pipes will not freeze. I also installed insulation in the floor at the suggestion of the plumber and inspector. The insulation is mainly to help sound-proof the area to the bedroom below.