The rain stopped for just a little bit this afternoon, so we went hiking on the Gold Creek Flume Trail, which is close to downtown Juneau. As far as I can tell, the entire trail is on top of a flume that takes water from the Gold Creek to a hydroelectric plant. With the exception of a small segment where a rock slide seems to be on top of the flume, it is a really easy trail to walk on, as you are on wooden planks. It is a nice hike through the woods with views of Gold Creek below and the mountains above. The western end is where the flume heads down the mountain. The eastern end seems to be where the flume separates from Gold Creek.

Tag Archives: Engineering

Risk Reduction Engineering for COVID-19

In response to some discussions I had seen about the use of HEPA filters to help with the COVID-19 crises, I wrote some thoughts on how effective I thought HEPA might be. Several people on Twitter stated they agreed with my statements. An HVAC technician (@JSTootell) provided some thoughts that I had never even considered such as the energy requirements on the buildings where a HEPA filter is installed as HEPA requires more energy (i.e. electricity) to run than normal HVAC filters. He also said the normal air velocity is super low because if you increase the air velocity and hence get more circulation, people complain about the noise of the air through the vents.

Some others have noted that HEPA filters, on a whole HVAC system or portable units in each room, won’t hurt to which I agree. One said they should be a part of a multiple layer approach to prevent the spread of COVID-19 to which I also agree. In fact, while I did not say it, that is part of my argument, HEPA filters alone will not solve the problem of COVID-19 transmission. I want to take a step back though and discuss this from an engineering perspective.

The basic, general idea in engineering is you find out what your design specifications are, you make some calculations and draw some designs to comply with those specifications based on proven information, you throw in some safety factors, and then you build whatever it is to comply with your design and calculations. If you want to build a bridge, you need to know before hand what are the design specifications. Is it for trains, vehicles (cars and trucks), pedestrians, or something else entirely? How many of the intended type of users will be crossing the bridge daily? What is the span of the bridge? What is the height of the bridge? What type of weather will the bridge will be exposed to? There are far more questions, but that is the general idea. You can’t design a bridge until you know what you are designing.

I currently work in human health risk assessment related to exposure to hazardous chemicals. It is not the same as risk assessment related to exposure to infectious agents, but there are similarities. With hazardous chemicals, the goal is to reduce people’s exposure such that they are not at undue risk to the chemical exposure. You can’t reduce risk to zero; it is simply impossible. With chemicals that cause cancer, generally you are trying to get the risk below one in a million chance of cancer caused by exposure to that chemical. Another part of this is who is at most risk. With chemicals, the people we are generally most concerned with are children or pregnant women as they can be more susceptible to harmful effects than healthy, non-pregnant adults. The risk requirement is one of your design requirements. If a person can be exposed to 100 mg/l per day (via ingestion) or 100 mg/g (via inhalation) of a certain chemical and not be above one in a million risk of cancer, then you have to figure out what needs to be done at a contaminated site or with contaminated drinking water to get their exposure (and thus risk level) below that number. This could mean filtering water or removing topsoil at site (to avoid incidental ingestion of contaminated soil or to avoid breathing in soil particles). What kind of treatment and how much treatment is needed to get below that concentration? That is one of your design requirements. Similarly the design and operation of water treatment plants is based on cleaning water such that the water has less than some amount of a contaminant before it is sent via pipes to the customers. Design requirements from water treatment plants is generally based less on risk calculations and more on state and federal requirements for contaminant levels in drinking water. These federal requirements are called Maximum Contaminant Levels. Water treatment plants must meet these requirements, and they are designed to prevent the people who drink that water from getting sick from microorganisms or chemicals in the water.

This leads me to designing a HVAC system with HEPA filters or the use of portable HEPA filters in buildings to protect against COVID-19. In order to design a system, you have to know the design requirements. It is absolutely fine to say you want to reduce virus particles in the air and reduce transmission, but that is not a design requirement. Reduce is a vague, qualitative word. Engineering requires quantitative requirements. If you only want to reduce particles in the air, then you will only reduce the risk by an unknown amount with no clarity on if that reduction is an acceptable amount to the occupants of the building. Reducing risk could mean that instead of 30% of the occupants of a building getting sick, only 20% do. I personally don’t find that to be an acceptable reduction. A design requirement is based on what concentration of virus particles can be in the air and no person gets sick from COVID-19. Perhaps your requirement would not be that stringent, perhaps you would be ok with one in a thousand people getting sick from COVID-19 based on the design. The design requirement can be based on people wearing a mask or not wearing a mask. Maybe with everyone wearing a mask indoors, they can be exposed to 10 virus particles per hour, but without a mask, they can only be exposed to 2 virus particles per hour. This is where infectious disease experts are needed to provide information as to the pathogenicity and virulence of the pathogen, which in this case is COVID-19. An engineer designing a HVAC or some other filtering system for a building is not the person to decide what those design requirements are. They need the infectious disease experts to state what concentration of a pathogen a person can be exposed to without getting infected. The concentration may be zero. The problem at this point is I don’t think we know how much COVID-19 a person can be exposed to without getting sick. Thus, if we don’t know how much COVID-19 a person can be exposed to without getting sick, how can we possibly design a system to prevent a person from getting sick.

I can already hear arguments that we just need to do something. We need to accept some risk but do some things to reduce risk, so we can get things back to normal. I don’t think most business owners are going to be willing to spend a non-negligible amount of money on some design that will simply reduce risk to an unknown and unproven amount. For a place of employment or a school, is it reasonable to ask people, especially children, to return to a building with an unknown risk if a system has been put in place that reduces the risk an unknown amount? How much money should employers and educational boards spend to reduce risk an unknown amount? If you are willing to accept some risk, then why spend money on something that may reduce risk by some unknown amount? Everyone is already spending money on masks, gloves, hand sanitizer, etc. which at least has been proven to reduce risk, but not eliminate it, by a reasonable degree from a cost benefit perspective. I spent $20 or something on two reusable cotton masks that I wash after use. That is a very reasonable cost benefit amount from my perspective even though I can’t calculate the risk reduction of the mask. How much money is reasonable to invest in either a whole system HEPA filter or portable HEPA filters when the risk reduction is unknown? An extremely quick internet search provides options for portable HEPA filters from $200 to $1200. Should schools buy one per classroom, even at the low price end, when there is no data to show they would reduce risk at all? The point is, reducing risk is good, but if you going to invest money to reduce the risk, it would be prudent to determine how much the risk is actually going to be reduced before you do it.

HVAC, HEPA, and COVID-19

I recently saw some discussions on Twitter about the usefulness of HEPA filters in schools and other buildings to protect the building occupants against COVID-19. There seemed to be a general agreement that HEPA filters could lower the virus particles in the air, but there was not agreement if this would help lower transmission of the virus and infections. There seemed to some non-biological scientists and engineers arguing that it would definitely lower transmission. Others wanted trials and tests. It was simple some said, less virus particles, less transmission. I am engineer, and I found these statements to be rather narrow thinking in consideration of transmission.

I want to explain more fully the flaws I see in the idea that HEPA filters will definitely solve the problem or will greatly help. I need to state first that I am not an HVAC engineer. HVAC by the way, stands for heating, ventilation, and air conditioning. HVAC engineers are the people who design the ventilation systems for buildings. They are also to blame for women always being cold in buildings by the way. The air conditioning design is based on old calculations that involve men in buildings, but I digress. However, my Bachelor’s degree is in chemical engineering, which means I have a good background in fluid flow. Air flowing through a building is fluid flow. Not the kind I normally work in, but fluid flow nonetheless. Also I am not an industrial hygienist. These are the people who figure out how to keep workers safe. I don’t think normal office workers and definitely not school children are their normal scope of work, but they could offer informative thoughts on this.

First, what is HEPA? HEPA stands for high-efficiency particulate air, and HEPA filters are basically really good air filters. Some technical information on them can be found on U.S. EPA’s website. I have really bad allergies, and I have a whole house HEPA filter installed in my house’s HVAC system. There is an initial mesh filter, a giant honeycomb type filter that traps particles then a panel that zaps the air with electricity to kill things. I clean it a couple of times a year. I still sneeze.

For the sake of argument, let’s say that HEPA filters remove all viruses, including COVID-19. For a HEPA filter to work, the virus has to get to the filter. Now we need to think about air flow in buildings, and how the air is going to get to the filter and more importantly how fast the air is going to get to the filter. Most modern non-residential buildings are designed with air ducts and other infrastructure (water and waste pipes, electrical cords, network cords, etc.) overhead in the space between floor above and the drop down ceiling with somewhat ugly acoustical tile. Think of all those movies and tv shows where a character goes into the ceiling and crawls around in the HVAC duct work to get to wherever to save someone or steal a jewel. Thus, in general, all the duct work is overhead, and so the inlet vents, the vents by which the air flows into a room, and the return vents, the vents by which the air leaves the room area, are all overhead. When air leaves the room, it flows back to mechanical works that cool or heat the air. This is where filters, HEPA or not, generally are. The air then goes to a blower which sends it back to the building and its occupants. In a house, the inlet vents are generally in the ceiling or the floor (in my house they are in both depending on the room), and the return vents are often in walls or ceilings. The vent where you place the air filter is the return vent. Thus in most houses, you filter the air after it leaves the room and before sending it to the mechanical works for heating or cooling.

That is the basics of building ventilation. Consider a classroom. Consider if ten children and one teacher are in a classroom, and one child is infected and coughs. Consider the air flow in the average classroom. When the child coughs, the aerosols, droplets, virus, spread out from the child. Unless the HVAC system is pulling the air up and out of the classroom continuously with really good suction, the virus can still easily spread to nearby people. Also, I want to emphasize the word “up” in my previous sentence. It depends on where exactly you are in the room as to the actual direction of airflow. In the office building I normally work in, my cubicle is directly beneath an inlet vent. I know this because I can look up and see it, and because I am always freezing, and because I can hear it when the air blower turns on. Air blows down onto me then outward to the side then pulled up a couple of yards away where the return vent is. I have not mapped out the exact airflow in the building, but you can feel it and make guess based on where the inlet and return vents are. In the vast majority of buildings, you do not feel a breeze. The air is not flowing at a high enough rate for paper to fly away. If paper is not flying away, the virus is probably not either. In my two-story house, there are two return vents, both in the halls. Air flows into the bedrooms, living rooms, etc. into the hall. If two people are in the living room, and one coughs, the cough is going to go out from the person and potentially right by the other person before it ever flows to the return vent. Also, like most houses, my air blower is not on continuously. The air is not always flowing. The same for office buildings. Buildings are designed differently, but I can definitely hear it when the air kicks on, which means it is not always on. If the air blower is not on, the air is not flowing, and virus, particles, etc. are not being pulled out of the space.

In graduate school, I worked in a brand new laboratory building. It literally opened the second year I was there. There was a common area with places to sit, talk, and eat and passages to the adjoining buildings. Off of the common area, where two halls that led to the laboratories. The building was designed for negative pressure. Air flowed from the common area to the halls then to the laboratories. It was perceptible. The doors to the halls, which required a card to open and swung open into the halls, would pull in because of the pressure they were under. You had to physically push the entry door back into place or an alarm would go off. The exit door, which swung open into the common area, would slam shut from the pressure. [Whether or not the negative pressure was too high is debatable.] The building was designed this way so that the volatile chemicals and infectious agents that we worked with in the laboratories would not get into the common areas and expose people. In the laboratories themselves, there were other precautions to protect people inside.

Normal office buildings and schools are not designed this way. They are not designed to be under continuous negative pressure. They not designed to be continuously pulling air away from the occupants. To a certain degree, they are designed to push air onto the occupants. If one person coughs, depending on where they are in the room and the air flow at the time, I would argue that the ventilation may help push the cough droplets from one person to another.

HEPA filters might be able to help solve the COVID-19 problem, but we need studies to show that they can. HVAC engineers and industrial hygienists would need be part of the solution and consider the design of buildings. Independent of COVID-19, HEPA filters are not a bad idea. However, they require more energy to use. Also, consider the time and expense of installing HEPA filters in all the buildings. You cannot just stick one into the system if the system is not designed for it. If it will solve the problem, most of us would say it is worth it, but it is not a problem that can be solved in a day or a week.

If I got anything wrong above, I welcome HVAC experts or filtration experts commenting below.

Edited to add: Someone who read my post stated that portable HEPA filters is what they are suggesting, not whole system filters. My argument remains the same. Assuming they mean one portable HEPA filter per classroom, if the filter is right next to the sick child, it might work. However one of the problems with COVID-19, is you don’t necessarily know who is sick. If the sick person coughs on the other side of the room as the HEPA filter, the portable filter, is going to pull the droplets from the cough across the room to the filter, potentially right by other people. It depends on how fast it pulls the droplets as to if another person would have time to breathe in the droplets, or for the droplets to land on their face. You really need studies to see if this would be effective.

PPE Basics

People are scared by COVID-19. This is understandable. Some people have started wearing personal protective equipment (PPE), mainly masks and gloves, although some are going for bonus points PPE like protective overalls, because they think the PPE will help protect them from COVID-19. It may, but it may not. I thought I might present just a few basics points for people who don’t normally wear to consider about wearing PPE.

What do I know about PPE you may ask. I am engineer and scientist. I have worn PPE in the field when taking environmental and industrial hygiene samples including soil, groundwater, urine, blood, air samples, and more. To earn my Ph.D., I worked in a lab that handled both chemical and biological samples. That is, one day I might have been handling urine or blood and needed to protect myself from pathogens, and another day I might have been handling chemical samples (or more likely part of a biological sample that had been placed into a chemical for processing) and needed to protect myself from chemical hazards. I am also HAZWOPER certified, and as part of the training, you have to dress in Level A and Level B PPE.

The most basic thing you need to know about PPE is first that PPE is essentially anything you wear that protects you from a hazard. In some places, jeans and long sleeves are PPE because they cover your skin from minor hazards. Steel-toed, leather boots are PPE that I have worn on a frequent basis when in the field as they protect my feet from many physical hazards including in at least one location I was working, rattlesnakes. [Not a hazard I was expecting on that site inspection, but, well, Texas.]

The second most basic thing you need to know about PPE is that it is not magical. PPE has to be worn correctly, and the correct PPE must be worn. For example, not all gloves protect against all hazards. In most of my work, I have worn nitrile gloves. Nitrile tent to be preferred over latex. The minor reason is potential latex allergy. However the main reason is that nitrile protects against more chemicals than latex. For most of my work, it is chemicals for which I need to protect myself. Most gardening gloves will protect you against some physical hazards like prickly vines, but they will not in general protect you against chemicals like pesticides you might be applying.

On the subject of gloves, gloves do not kill bacteria or viruses. If you are worried about viruses getting on your hands because you are touching a grocery cart for example, and so you decide to wear nitrile gloves, if you dispose of the gloves after touching the grocery cart and don’t touch anything else, then gloves may have protected you. However, if after touching the grocery cart with the gloves, you then touch your phone or your face with the gloves, then the gloves have done you no good. You have just transferred any viruses from the grocery cart to your gloves to your phone or face, just as efficiently as if you had not worn gloves. A week ago, I went to Costco and went first to the bathroom. When I was washing my hands, I noticed a woman washing her hands while wearing latex gloves. I simply don’t want to know what else she touched with the gloves before doing this or after.

A final note about gloves, there is a definite technique to how to remove them. The goal is to remove them without touching the outside of them. There may possible be another way, but the best way I have found to do it, is place one gloved finger on the outside of the other hand’s glove, near the wrist and carefully pull that other hand’s glove off, sort of rolling it off. Then with the now glove free hand, place your ungloved thumb under the other glove near the wrist and pull that glove off. Easier to show than explain.

Masks and respirators are designed for different types of protection, and it is critical that they be worn properly and for the correct use. Surgical masks are really more to the protect the patient from the surgeon sneezing or coughing on them than to protect the surgeon from the patient. Surgical masks can protect the wearer from splashes or larger droplets or to a certain extent large particles, but that is about it. Surgical masks do not provide even a decent seal around the face, so they do not protect from airborne viruses, bacteria, chemicals, or even small particles. If you don’t believe me, believe the FDA.

The now popular N95 masks can protect against some particles, viruses, and some other things if worn correctly. First, it is important to consult the manufacture’s information as to what they are designed to do and not to do. Second, it is critical that the wearer has a good seal. What does that mean? It means the edges of the masks must fit snugly against the skin for the entire perimeter of the mask. Men, you have to be clean shaven. Even an evening stubble will prevent the seal. N95 masks have a piece of metal that goes over the nose. That metal needs to be adjusted to get a good seal over the nose. Both elastic bands for the mask must be used to increase the fitness of the seal. Finally, masks get saturated. They can only be worn for a certain period of time before whatever you are breathing in breakthrough the mask.

I can’t emphasize enough how critical seals are. When I was graduate school, for the field work I was doing, I needed to be able to use a half-face respirator. That required me to first get medical clearance to wear the respirator. Second, I had to be fit-tested for the specific respirator I was going to wear. Different manufacturers make different size masks, and they don’t generally agree with each other. Hence I was fit-tested to wear a specific manufacture’s specific sized mask, and that was the one I wore throughout my field work.

Finally with respirators and masks also, the manufacture will state what the respirator or mask is designed to protect you from. If you go to a hardware store and look at respirators, you will notice that some respirators are for lead, some for particulates, some VOCs, and some will do a combination. A mask to protect from VOCs and PM10 is common. If you are going to work with VOCs, and you get one that is only for PM10, you will not be protected at all. Cartridges for respirators have to be changed frequently. Every two weeks is a common changeout time.

Those are the basics. There is really a lot more to understand about PPE, but those of the initial basic critical points to understand if you are thinking about wearing PPE to protect you from a virus or other hazards.

COVID-19 Environmental Effects

For three days following September 11, 2001, civilian planes were grounded in the United States. It has been postulated that the diurnal temperature range in the U.S. was affected by the lack of contrails created by planes. Contrails, condensation trails, are formed by planes flying at high altitudes. It has been hypothesized that they can act as natural cirrus clouds for at least a short period of time after they form by absorbing long- wave radiation at night and reflecting more shortwave radiation into space throughout the day. Hence they can affect temperatures. The theory that the lack of contrails for three days following 9/11 affected the weather has been disputed though. The three days following the attacks formed a natural experiment that scientists looked at after the fact, but because the planes were only down for three days, that is not much time to have enough data.

Almost the entire world is in the middle of an unprecedented event because of the novel coronavirus often referred to as COVID-19. Anyone who can telework is. People are unfortunately getting either laid off or furloughed because the tourism and entertainment industries have taken such a hit. Restaurants are being forced to close or are only offering carryout service. People are not traveling if they don’t have to either to commute or to go to another city. Governments across the world are telling people to stay home if they are able, or in some cases are ordering them to stay home.

What effect will this have on the environment? Northern Italy has been hard hit by the virus. People in Venice are reporting that the water is the clearest it has been in decades. They are attributing that to the lack of boat traffic. At least initial reports seem to indicate that air pollution has decreased because of lack of vehicle traffic. I am curious though about all the impacts. Vehicle traffic would seem to be the most obvious. Most people are not leaving their house unless they have to, but deliveries may be going up. Airline traffic is definitely down. Train travel is probably down. Inner-city buses and subways are decreasing service due to decreased demand.

What are the other effects though? Water usage may not change in total, but I would hypothesize that it may change temporally. There is a general routine on weekdays. People wake up. Many take showers. They leave their house and go about business. They come home and then start housework among other things like running the dishwasher. Perhaps they do laundry, or perhaps like many the laundry is done on weekends. If a significant portion of the population is teleworking or just plain told not to come to work, they will probably run washing machine or dishwasher in the middle of the day between conference calls. Thus water demand instead of peaking in the early morning and then again in the evening may average out across the day. Same for wastewater flow.

Electricity may be even more interesting. In the early morning and late evening, more electricity is used by people in their residences. In the middle of the day, more people are at businesses or schools, so they are using more of their electricity there. Similar for telecommunications. What about when everyone is staying home and teleworking? In theory, the offices should use less electricity assuming there are smart devices there to not turn on lights if no movement or the HVAC reacts to need in the offices. However, the homes are probably using more electricity. How will this affect the electricity grid? Electricity needs will be more spread out around residences and less in concentrated urban areas. The high speed internet at the office is probably not going to be used as much, but will the internet from residences be strained from all the traffic? My employer has been having remote access issues, which I have no doubt stem from the number of employees working from home. How will this affect the telecommunications grid? Cellphone traffic will possibly go up, and landline traffic may go down.

Conversely, will trash be generate less, the same, or more trash? Not going out would in theory generate less trash. However, we are probably going to go through more gloves, masks, and other personal protective equipment in the coming months, and not just from medical personnel. Take out from a restaurant generates more trash at least from the consumer than eating in, but as people avoid restaurants in general, no trash is being generated there.

I am not in any way shape or form arguing that the virus may be good or bad for the environment. People are dying. I am not losing sight of that. However, I think it is likely that the virus will affect the environment, and I am curious how. It seems likely that self quarantines or at least staying home as much as possible may last weeks if not months, so that may be an adequate amount of time for an affect of some sort to be seen. Question is, what will the affect be?

Richmond Canal Walk

I am continuing my quest to see all the state capitols. I am in Richmond this weekend to see the Virginia state capitol. However, today, I just wandered around. I spent most of the day walking along and near the Richmond canal walk. Richmond has a couple of disjointed canal that were originally part of a large system so that ships could avoid the James River rapids. The canal walk is lovely. The original building of the canal and the restoration of it are impressive engineering projects. They have restored much of the system, and you can even take a boat ride along part of it. [I did, and some of those photos are included.] Railroads and then highways were built alongside and on top of parts of the canal system. My tour guide on the boat ride noted that there is one part where you can see 18th century (the canal), 19th century (the railroad), and 20th century (the highway) transportation systems all in a single frame. I thought that was an interesting and insightful observation. The canal also is both inside and outside the Richmond flood wall, which is another impressive piece of engineering. A canal was built to bypass the James River rapids, and a wall was built to protect against James River floods.

Manure Slinger

One of the things I like about my job is that there is never a dull moment, and I never know what I am going to be doing next. Will I be reading a toxicology assessment? Will I be tracking down a CASRN? Will I be trying to explain in plain English some highly complex scientific issue? Will I be doing a statistical analysis? Will I be trying to figure if some hazardous chemical may or may not be associated with some particle source of contamination? Will I be trying to cleanup a database that has 11 (11!) different valid and invalid synonyms for cis-1,2-dichloroethene? It changes everyday.

A couple of weeks ago though set a new level for “ok this is different.” There was an urgent request from a big wig where I work to do some quick calculations on biosolids. If you don’t know what biosolids are, they are essentially treated sewage sludge. Wastewater treatment plants, which treat domestic wastewater (i.e. the stuff that goes down your sink and toilet), generally have three types of streams that exit the plant. The first is wastewater effluent, which is treated water that is clean and can be released into a river or lake, or if it treated enough can be used to water golf courses or things like that. The second is the sludge. The sludge is generally water with some solids. Sludge is treated, watery poop. It depends on the wastewater treatment plant as to how much treatment and how watery the sludge is. Some sludge is dewatered and composted on site, such that by the time it leaves the plant, it is pretty much just compost. Some is treated less. It depends on the state and the degree of treatment as to what happens to the biosolids. The states have different regulations to the final disposition of the biosolids. Biosolids can be incinerated, landfilled, or land-disposed. The third stream that leaves the wastewater treatment plant is only a stream in an engineering sense. It is non-degradable solid stuff that is screened out as soon as the wastewater enters the plant. This includes condoms, “flushable” wipes, rags, and all the other weird stuff people flush down the toilet or down the drain because out of sight is out of mind. Seriously though why on earth do so many people think condoms are flushable? All that human-made stuff (ok stuff made by humans but not made by the human gastrointestinal track) that people flush down the toilet (because the police came busting in?) or pour down the sink (because clearly you are not thinking about how much your are going to have to pay the plumber to clear you’re drains?) is screened out and sent straight to the landfill or incinerator. This stuff plus the fat and grease people put down the drains are what forms fatbergs.

It is the land-disposal of the second stream of biosolids that was involved in the urgent calculations I needed to do. Essentially, if the biosolids are highly treated at the wastewater treatment, composted at high temperatures for a long enough period of time, and tested for certain contaminants, mainly heavy metals, as required by law, and the state allows it, then they can be used as fertilizer on land. This is not a new concept. For hundreds of years, night soil, as it was called then, was collected and used as fertilizer. It wasn’t even treated. The composting at the wastewater treatment plant, if done correctly, should kill the pathogens in the poop. The controversial question though is whether or not the biosolids contain chemical contaminants that would not be removed by composting. That is a whole other subject.

My task though was to do some calculations on scenarios involving biosolids. While I am familiar with the concept of biosolids and their final disposition, I needed to do some research on their physical properties. Turns out, finding an average density for biosolids is much easier said than done. The internet gave me answers that were all over the map. The other part of my calculations required me to make some assumptions about how the biosolids were transported to fields or farms if they are land applied. I had never actually considered until that moment how watery, treated poop is transported. As weird as I am considering I travel to visit landfills, wastewater treatment plants, and rail yards and considering how I eagerly read books about poop, I never really considered the transport of biosolids. [I cannot stress enough how much I loved Rose George’s The Big Necessity.] Time was of the essence, we needed some sort of estimate for the question presented, so I grabbed what seemed like reasonable numbers for the physical properties of biosolids and how they transported, and I did my best to calculate with some sort of reasonable confidence the numbers that would answer the question being asked by the big wig. I actually rather enjoyed this rather unusual request. I learned at least a little bit about the details of biosolids.

This week though, the same question came up. I was asked to confirm my calculations, but I was given more time to consider the question. Thus, I had been considering the question for a couple of weeks, and I had had time to ask colleagues as to good sources of information on biosolids. I was able to devote more time to finding good estimates for the information I needed. In the course of my research, I learned to my great joy that biosolids and regular manure are often (normally?) land applied using an invention called a manure slinger. I swear this is true. Humans invented a device called a manure slinger, and in the grand tradition of engineering inventions, it does exactly what its name implies: it slings manure. I hope you can understand my joy that this exists. It is similar to my joy when I discovered that humans had invented a fish cannon that true to its name is a cannon that shoots fish. Engineers aren’t really that creative in the naming department. Heat exchangers exchange heat. Catalytic converters use a catalyst to convert one thing to another. [In the case of your car, it uses a catalyst to convert harmful gases to less harmful gases.] Circuit breakers break an electrical circuit. This leads to my new favorite invention, the manure slinger which slings manure. Do an internet search on manure slinger. You will find photos and videos of them. Videos of a manure slinger slinging manure brought me even more joy. Yes, I am weird, but if you have ever visited my website before, you should know that by now.

Now I was armed with good experimental information on the physical properties of biosolids and with very good information as to how they were transported and land applied. I redid my initial calculations checking my work and with far more confidence in the answer. I could prepare an answer for management to send to the big wig with as much confidence as could be expected on the somewhat unusual question being asked. Further, today I was asked to help prepare communication material regarding the question that had been asked about biosolids. To my even greater joy, than simply learning that manure slingers exist, I was able to write (I swear) scientific information for the communication material that involved the phrase manure slinger numerous times in a paragraph. I have no idea if the communication material will ever see the light of day, and if it does, if the communication people or management will be fuddy duddies and remove the phrase manure slinger and substitute with something far more mundane sounding, but at least initially, I had the joy of writing a completely serious, scientific paragraph using phrase manure slinger. It was a great way to end the week.

Lawn

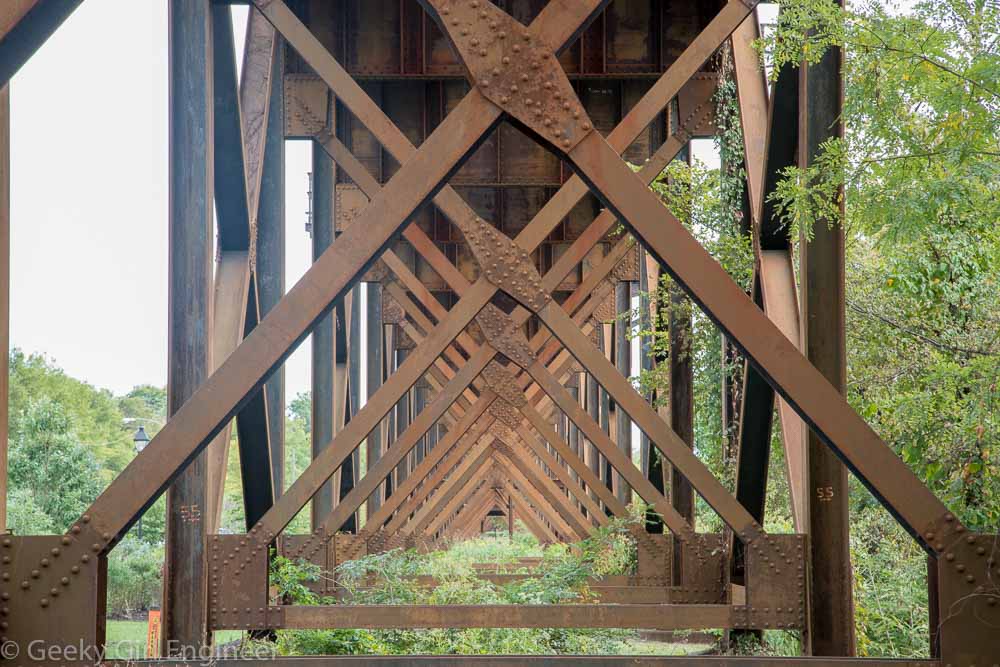

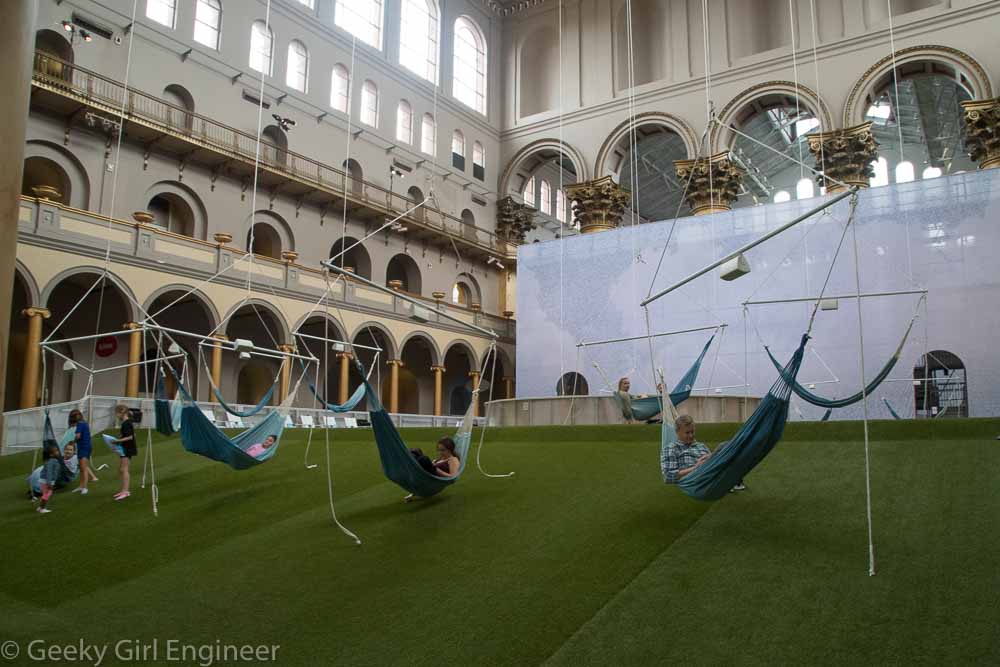

Every year the National Building Museum has a fun exhibit that takes up most of the atrium of their building. This year it is Lawn. They essentially built a giant sloping lawn on scaffolding, complete with hammocks, chairs, and lawn games. They made the building’s fountain part of the exhibit. They also piped in a summer soundtrack of noises like kids playing and lawn mower. I am not sure how I feel about the noises, especially the sound of a swarm of mosquitoes. However, it is a nice place to just chill out, and children clearly love it, especially the rolling down the slope part.

This year, they had tours of the exhibit discussing how it was built. Of course I had to go to that. We were able to go under the exhibit, which was rather cool. The structure is a giant scaffolding set that supports the lawn and observation tower. The structure is entirely self supporting. It is not supported by the building, except the floor of course. They also have hammocks that hang from the roof trusses. The hammocks are anchored to the lawn though, otherwise goodness how far people would try to swing them.

F.J. Horgan Water Treatment Plant

The F.J. Horgan Water Treatment Plant was one of my top two reasons for coming to Doors Open Toronto. Sadly, no wastewater treatment plants were open for the event, as I find them more interesting than water treatment plants. However, water treatment plants are still interesting. This plant was even more interesting than I initially thought it would be because I am fairly this is the first water treatment plant I have been to where they use ozone for the initial disinfectant. This is the second water treatment plant I have visited in Toronto. The first Doors Open Toronto I came to, I visited the absolutely magnificent R.C. Harris Water Treatment Plant. F.J. Horgan Water Treatment Plant is not as beautiful, but it is interesting none the less.

The plant’s water intake is from pipes in Lake Ontario over 2 km from shore. It is then pumped to the plant and then up from the pipes which are (I think) nine stories below the surface. The plant sits on cliffs high above the water surface. Ozone is added to the water. Ozone disinfects the water. The ozone is made at the treatment plant from liquid oxygen. Before the water leaves the tanks where is contacts ozone, sodium bisulfite is added to remove any left over ozone.

Coagulant is then added to the water. Coagulant causes certain ions and tiny particles to start to come together to make bigger particles, which are easier to filter out. The water is pumped to sediment filters. The filters have a lower sand layer topped with a carbon layer. The filter tanks are huge, but so are the pipes in the building.

After the water has been cleaned, chlorine is added. The water has already been disinfected at this point, but a residual disinfectant is needed to kill any bacteria the water may encounter in the distribution system on its way to customers.

Eglinton Maintenance and Storage Facility

I am in Toronto for Doors Open Toronto. When any city allows people to visit a rail yard or water or wastewater treatment plant, I will be there. One of the places that was on the top of my list to visit is the Eglinton Maintenance and Storage Facility. It houses the Crosstown Light Rail Vehicles where they are inspected, cleaned and maintained. It only opened in January 2019, which was evident because it is still very clean and looks barely used. It is a well designed facility that appears to have been designed with the human worker in mind.

The facility has a train wash, paint booth, and numerous bay for maintenance. The maintenance areas have pit to work underneath the trains besides the platforms to work on the side or inside the trains, but it also has balconies so that the workers can get to the top of the trains.