The master bathroom renovation is finally completely finished. The bathroom is small, but it has all the features I need and want. It is functional, and I love it. I previously wrote about the cabinets, but the final piece, an open shelving unit that sits on top of the countertop has been installed. All the cabinetry is from Tuscan Hills, and while most of it is standard cabinetry, some of it, especially the false bottom of the wall cabinet for access to the bath mechanics is custom. The tub is an MTI Andrea 14, and I must admit, after having taken a bath in it, it is even bigger than I realized, but it has whirlpool jets and air bubblers and is quite lovely in which to soak. I used frameless glass for the shower and simple, clear glass vessel sinks, so that visually they take up as little space as possible. I previously wrote and posted more detailed photos of the shower, so I am not posting too many here. The plumbing fixtures are all Grohe’s Atrio line. I used Moen’s Iso line for the towel bars and rings, robe hooks, and toilet paper holder, and I used Thomas Lighting’s Pittman fixtures for the vanity lights and wall sconces in the water closet.

Tag Archives: Interior Design

Vanity Backsplash Tiled

This weekend I tiled the vanity backsplash. It is a rather high backsplash as I wanted the tile to go at least as high as the wall faucets. I wanted to tile a border around the recessed medicine cabinets, so I decided just to bring the backsplash up to the base of the medicine cabinets. Also, I changed the original design for tiling in the shower, and I have a bunch of left over glass tile, so I might as well use it. The height of the marble tile was determined by the height of the electrical box because I wanted the same tile type surrounding the electrical box, so the cover would lay flat.

Shower Floor Tile Laid

I laid the shower floor tile on Saturday. The tile is the same marble that is used on the bathroom floor. The bathroom floor tile is 12 in x 12 in tile with a brushed finished. The tile in the shower are smaller pieces that have been tumbled into odd shapes and placed on a mesh to give a cobblestone appearance. I really like using this type of tile for a shower floor because it is naturally slip-proof and feels really good on the feet. The only problem with using this type of tile though is fitting the different pieces together. They don’t line up the way regular shaped tile does. I removed pieces from the mesh of unused tile to fill in any gaps where the tiles met or where a tile met the edge of the shower. It is a bit of extra work, but I really like the appearance and think it is worth it.

Phase 3 Deconstruction Continues

I did more deconstruction this weekend, and all that is left to demolish is the flooring, a few interior studs, the stud headers, and the shower pan. I am turning it over now to the carpenter to remove all of that. I realize now that this phase of renovation should not have been done during the coldest time of the year. Because of the condition of the drywall that made up the ceiling and all the reconfiguration that was needed, I removed all ceiling drywall. I also removed the attic insulation above it as nothing would be there to support it, and I need to put in better attic insulation anyway. This means though that this area is at the same temperature as my attic, which is freezing, and I am going to have an awful electric bill next month. I have a plastic sheet securely hung in the doorway to the bedroom, but still it not a really good air barrier.

I removed the vanity by hammering the crowbar in-between the plywood sheet that made the counter base and the layer of plywood it sat on. The glue that held it cracked fairly easily, and I could the lift the whole thing out. After doing that, the rest of the vanity was fairly easy to disassemble with a bit of hammering and pulling. It was not all that well constructed. Once I removed the vanity, I discovered that the original floor in the bathroom was tile that matched the vanity countertop tile. That was interesting and a nice touch on the original design. I don’t have a clue why they removed that tile, added another layer of subfloor, then put new tile on top.Then again, I have no clue why the later home “renovators” put insulation in the three walls that made up the side of the shower because the shower was completely interior to the house. Oh well, it is almost all removed now, and soon all of it will be replaced.

More photos can be found on Home Renovation Phase 3.

All the various tile flooring in the bathroom. The aqua square tiles were underneath the vanity and match the countertop. The large off-white ones were in the space between the two vanities.

Warning: Engineer Renovating Her Home

Sometimes I think I should come with a warning label: “Warning: Micromanaging, long-term planning, detail obsessed, anal retentive, constantly questioning engineer.” At the very least, when it comes to home maintenance and renovation, I should warn people of that. In truth, I think some of my personality traits that can probably be annoying at times, also make me a good engineer. Engineers have to think both short and long term. We have to look at both the big picture and all the tiny details. Sometimes, in my personal life, I am just not sure people are prepared to deal with those traits. I am not actually saying I would change myself if I could; I’m just saying sometimes people are unprepared to deal with someone like me.

I am currently planning for Phase 3 Home Renovation. I actually started planning for it during Phase 2. I changed the layout of the second floor of my house during Phase 2, and part of those changes were to prepare for Phase 3. One of my overall goals with my home renovation was to create a nice master bedroom closet and bathroom with a tub. The original closet was two reach-in closets that barely had enough space for two people, and the original master bathroom was tiny. It had two sinks on a small counter space, a small shower only stall, barely any storage space, and a toilet. I really wanted a nice whirlpool tub and more space. The master bedroom is next to the living room, where I had wanted to open the space up with the dining room and kitchen. Therefore, while planning for Phase 2 where I renovated the living room, dining room, kitchen, and family room, I drew, redrew, and kept redrawing the configuration of the second floor until I could have an open layout with the common rooms and also a nice master closet and bathroom that I wanted. In the final plan, I stole a six foot wide space the length of the living room from the living room and used that space to form a new master closet and a new water closet (for the toilet) that will connect to the new master bathroom. That new space was created during Phase 2. I also moved the doorway to the old master closet and bathroom to prepare for Phase 3. The door needed to be moved to fit the new bathroom configuration. I moved the doorway during Phase 2 because Phase 2 was when I was having all structural work done, and the doorway is in a structural wall. I created a 3 ft by 6 ft dead space behind the new master closet, between my master bathroom and living room that will become the water closet.

Thus, I planned the new master bathroom when I was planning Phase 2, even though the bathroom would not be constructed until Phase 3. Now I just need to get the details planned. The cabinetry will be constructed by a custom cabinetry company, so that is no issue. Much to my surprise, main problem I have found has been finding a bathtub. I really want one with both a whirlpool and air massage, i.e. one with both a water pump and air blower. Finding one with both is not that difficult for dimensions I have, but finding one with the pump and blower on the left side of the tub is. Evidently, everyone is supposed to configure their bathrooms to have them on the right side. [In case you are not familiar with these types of tubs, you have to have access to the pump and blower in case they need service.] I am dumbfounded quite frankly that everything is configured for things on the right. With the vast majority of tubs, I can’t simply rotate the tub 180° because the drain has to be in a location that the plumber can reach to hook it up to the piping. Rotating most tubs would cause the drain to be in a location that the plumber simply wouldn’t be able to reach. After much searching, I finally found a tub where the manufacturer custom makes all tubs and with several models, they can reconfigure it to put the pump on the left side. Now I need to know the access size that is required for their tubs because I am planning to have tall cabinet to the left of the tub platform. The bottom of the cabinet will essentially have a false side that will give access to the pump and blower. The cabinetry company said they can figure out how to do it; they just need the dimensions. Therefore today, I’m on the phone with the plumbing supply salesperson who is helping me find a tub. I’ve got it narrowed down to one brand, and I’m asking a bunch of questions. I’ve downloaded the specifications and other information from the manufacturer’s website, but I still can’t find the exact access size that is needed. The salesperson finally says he is just not sure, so he is going to conference call me with a guy from the manufacturer. It was perfect, and the manufacturer guy went through all the details I needed. He said once I am finally ready to order, it would be best to get a specifications drawing and mark it up to show exactly where my cabinet will be and how much access I am leaving, and they can move the pump and blower a bit to give the best access. Now I need to take their specs sheet and mark it up and send it to the cabinetry company so that they can do the same.

This is why I don’t use general contractors. I hire all the contractors: carpenters, plumbers, electricians, etc. I buy almost all the supplies, or at least the supplies that affect the design and aesthetic. I micromanage everything, and when I have used general contractors in the past, I generally drive them crazy. There is no point to me hiring a general contractor because I micromanage everything so much I am not getting my money’s worth from them since the point of having a general contractor is that they manage all the sub-contractors and details. Also, I do a lot of the work myself, so I don’t need a general contractor to manage me. I plan long term ahead to make sure everything will work. I try to plan for every single detail. I will if necessary demand that I speak to the actual person on the factory floor to get the detail I need to know that affects the next detail. I will repaint a wall three times until I get the color I want, but I’m not going to tear up tile, so I want the space planned out correctly from the beginning. I call the county’s building permit department and speak to the inspectors myself to make sure I know what code requires, and sometimes I demand that contractors do things that go beyond code when I don’t think code is enough. In most of my renovation work, I tear a room down to the studs and subfloor because in this house, I just don’t trust anything that was done beforehand. Sometimes it is just easier to start all over anyway. Yes, I should come with a warning sign.

Useless Installation Directions

Today I installed two new wall mounted light fixtures on my front stoop to replace the old ones. The lightbulbs had burned out in one of them, so I decided to change the light fixtures sooner than I originally had planned. Yes, changing the entire light fixture because the lightbulbs burned out, is a little extreme, even for me, but truthfully the old one was so thoroughly rusted, I could not get it apart to change the bulbs. I wanted new light fixtures that would be more modern and allow for more lightbulbs, so more light would be produced anyway.

I’ve installed six light fixtures already, two wall mounted and four hung from the ceiling, so these two should not be a big deal. I keep forgetting just how useless all directions that come with these things tend to be though. Yes, as a female, even when I am sure of what I am doing, I still tend to read the instructions. I’m funny that way.

Why are the directions so useless? First, the one type of direction I would like for them to have, they almost never have, and that is how to change the lightbulbs. I’m serious about that. I’ve lost track of the number of fixtures where I’ve uselessly unscrewed various finials and nuts in hopes of separating some piece that inevitably is welded together to try to find a place that is large enough to reach the lightbulb. The new light fixtures I installed today are no exception. I unscrewed several finials only to realize a piece was welded. I finally realized it is possible just to stick my hand through the bottom opening and carefully swing the light piece to change the lightbulbs, but I have to be careful. Another annoyance with these fixtures is that the glass sides are held in such a way that during shipping, some of the slipped out of place. Part of the reason I was unscrewing finials was to figure out the best way to get the glass sides back into place. Again, I ended up doing it really carefully and slowly through the bottom.

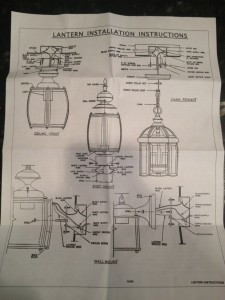

The second reasons most of these directions are useless is that evidently companies can only afford to print one set of directions for their entire line of fixtures. Below is the single piece of paper that came with these fixtures.

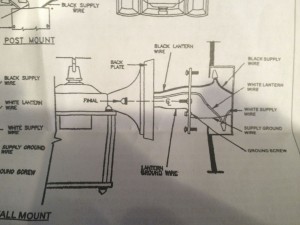

One sheet of paper for five different types of fixtures. Seriously? Does it really cost that much money to print a different one depending on the actual fixture in the box? Perhaps if they did, YOU COULD ACTUALLY READ THE DIRECTIONS. Here is a close up of the directions that, in theory, pertain to my fixture.

Yes, on the back were written directions also, but they can be summarized as 1. Turn off breaker. 2. Black wire to black wire. 3. White wire to white wire. 4. Ground wire to green grounding nut. These are of course great, and you, of course, can get them from anywhere on the internet. The best part of all of these directions is that they are somewhat wrong. If you look at the drawing above, the fixture hangs from a crossbar that is mounted to the wall box. This is completely standard. HOWEVER, this is the crossbar that came with my light fixture.

Needless to say, this threw me for a loop. I figured out the reason for it fairly quickly. Crossbars are always mounted to the wall vertically, but the new light fixtures required a horizontal mount. Thus one bar is to mount to the box, and the other attaches to the fixture. Great, no problem, but it really would have been nice if, oh I don’t know, THE DIRECTIONS HAD MENTIONED THIS IS LITTLE CHANGE FROM STANDARD. Even better, one of the fixtures had the screws on the wrong bar. That is, in one of the boxes, the screws needed to mount the fixture to its crossbar, were screwed into the other crossbar. Yes, I did figure out after several frustrating minutes that it does make a difference which crossbar goes to which. It affects the way the crossbar sits in the box and hides behind the fixture.

These directions weren’t even the worst ones that I have seen. The chandeliers that I installed had really useless directions. This is mainly because like all fixtures, they came with the standard directions of black wire to black wire and white wire to white wire. The problem was that the chandeliers did not have either a black or white wire. They had silver wires with clear coating. One had a little sticker labeled “N”, and the other had a little sticker labeled “L”. I just looked at these things wondering WHAT IN THE FLYING FIG IS N AND L? I know what black wire, white wire, bare wire, and even red wire from the wall are. So now there is N and L? Being the chemical engineer I am, I’m think of black as the “hot” wire and white wire as the “cold” wire, so why aren’t they labeled H and C? Ten minutes of internet searching later, I find out “L” means live or line, depending on your source, and thus connects to the black wire, and “N” mean neutral, and thus it connects to the white wire. However, most importantly, WHY THE HECK COULDN’T THE INSTRUCTIONS THAT CAME WITH THE DAMN FIXTURE SAY THAT?

The light fixtures I installed today did however have completely unneeded directions. Below is a photo of the back of the fixture.

The top sticker on the lower right has the completely unhelpful directions “Wall Mount Only [up arrow] This End Up.” Now if you only saw the fixture like this, those might actually be useful directions. However, if you look at the whole fixture, you would notice that the interior of the fixture where the lightbulbs screw in, hangs from the top of the fixture. Therefore, anyone with a passing understanding of GRAVITY would figure out that that end has to be up. So, I’m so glad they put that sticker on there.

Let me be clear, these directions are for do-it-yourselfers like myself. A professional electrician doesn’t need any of them. Thus, why are the directions so damn crappy? Are they to discourage do-it-yourselfers? Do they actually think these directions are helpful? Exactly how much would it cost to print different and readable directions for each type of fixture? Exactly how much would it cost for the design and/or manufacturing department to keep the department who creates these completely unhelpful directions informed when they change important aspects of the design, like using wires labeled N and L instead of black and white wires?

I did eventually get the new fixtures installed, no thanks to the directions. They look lovely, and no duct tape was required, just persistence and experimentation. Each fixture holds four lights as opposed to the old fixtures, which held two, so now there is more light produced. I think they might look slightly modern for the house, but I am planning to eventually replace the front door, and then I think they will work better. Also, the house really needs to be painted, but they has to wait a bit. WIthout further ado, the old and new light fixtures.

Master Closet Shelving

As part of Home Renovation Phase II, I stole space from the living room to create a walk-in master closet. The master bedroom had a small walk-in closet that led to the very small master bathroom. In Home Renovation Phase III, planned for sometime next year, I intend to create a nice size master bathroom using both the old master bathroom and closet. Thus, during Phase II, I created the new master closet. It is not spacious, but it is workable and has plenty of storage room for two people. It includes tall hangings, double hangings, shoe shelves, clothes shelves, and drawers. It is 124 inches long and 72 inches wide. That leaves the standard 24 inches for hanging areas on both walls and a 24-inch aisle. I bought the components from Closets To Go, and the color is Sunset Cherry. I really like the way it came out, but I would like to have a conversation with whoever wrote the assembly directions. Why is it so impossible for companies to actually check their assembly directions for accuracy? Also, there were a few issues that I solved using the engineer’s standby of fixing it by taking a hammer and banging the crap out of it.

With the master closet completed, Phase II of my home renovation is finally done 13 months after it was started. Yes, it took a long time, but I did much of the work myself.

What Not to do with Metal Covers

Geeky Girl Engineer’s Home DIY Tips for Morons

All houses have numerous cover plates for wall openings such as electrical outlets, light switches, and vents. The cover plates can be fancy or plain and come in various materials. Vent covers are normally metal, but specialty ones come in different materials. For two floor vent openings in my family room, I bought unstained white oak covers that I then had stained and sealed to match the hardwood floors in that room.

Light switch and electrical outlet covers are normally plastic but can also be various materials and colors. In my kitchen, I used stainless steel light switch and outlet covers to match the stainless steel tiles in the backsplash and the stainless steel appliances.

Thus, you don’t have to use the standard type covers. You can buy fancier ones to coordinate with your decor. You can also buy covers that are specially made to be painted or wallpapered so that they really match your walls. However, these are special ones. You can’t, or rather you shouldn’t, paint any metal cover. If you paint metal, it needs to be primed properly, and if you want the paint job to look nice, it needs to be applied carefully, preferably it should be sprayed on for a really nice, smooth coat. Otherwise, you get this:

I’m not sure if the photo really shows how bad it looks. The paint is chipping all over. Brush marks can clearly be seen, and in some places, the paint pooled, making the coat very uneven. Most importantly, if you refuse to heed my advice on this, please, please, take the covers off before painting them. Don’t paint them while they are on the wall. If you paint them while on the while, this happens:

See the lovely lines where the cover was? That is due to a thinner coat of paint where the cover covered the wall. Here is a similar outcome with the vent cover.

The very worst part was that the paint had flowed underneath the cover and essentially glued the cover to the wall. I had to use a flat-head screwdriver to pry the covers off the wall. In some places, it didn’t come off cleanly.

So please, don’t do this. Your house’s future owners thank you.

Hacking a Chandelier

As part of my home renovations, I have been installing new light fixtures, including several from ELK Lighting’s Elysburg line. I wanted to use a three light chandelier in the downstairs foyer by the front door and at the second floor landing at the top of the stairs. The only problem is that they hang 22 inches from the ceiling (at their shortest), and since my house has 8 foot high ceiling, this means the chandelier is hanging a little low for an area where people are going to walk. As with all chandeliers, it came with chain to allow it to hang lower, but there is a limit how short it can be. Thus, I decided to hack the chandelier to make it even shorter. Here is the chandelier at its shortest as designed.

The way the chandelier connects to the outlet box is pretty standard.

The simplest way to shorten the fixture seemed to be to eliminate the screw collar loop, clip ring, and canopy nut by somehow connecting the light fixture screw directly to electrical box’s screw pipe. The problem of course is they are two different diameters and threading size. I considered using a bolt that was the same size as the fixture screw, in place of the screw pipe, then just connecting them using a coupling nut. However the light fixture screw is a M10 x 1.0, and after a half hour of internet searching, I couldn’t find a single vender for that size coupling nut. Another method that I thought of later, was to bring the light fixture screw directly to the box crossbar using a nut, then drill holes through the canopy and use screws through those holes to hold the whole fixture up. The problem with that is that I was a little weary of drilling holes in the canopy in case I messed up, and also, I would need decretive screw caps to cover the screws, and I didn’t know how to find those.

What I did, was searched to aisles of Home Depot in search of something I could use to connect the pieces somehow, and I finally came up with the following solution. These are the materials I used. I used the chain that came with the chandelier, a nut to fit the light fixture screw, and a crossbar adjustment kit I found in the electrical aisle. I bought the crossbar adjustment kit solely for the piece that in the photo is outside the package it came in. I have no idea what the piece is, but it looks like to two very strong washers held apart in a parallel manner by a bar.

Here’s what I did. I put the parallel washer thingy piece on chandelier screw, then used the nut to hold it on. I then cut one of the chain links in half and used it to connect the top part of the parallel washer thingy to the chandelier’s screw cap. [You will note that as an engineer, I sometimes use highly technical terms like “thingy”.] I had to use a pipe wrench to bend the cut chain link into a closed loop. It’s rather strong.

The finished chandelier now looks like this. I was able to shorten the entire chandelier by about two inches. Not that much, but enough that hopefully less people will hit their head.

So that’s how I hacked the chandelier. If anyone out there has any suggestions for a better way I could have done it, that does not involve welding, I would love to hear it. Please leave a comment with suggestions.

A Curtain Rod from Door Knobs and a Wooden Dowel

Here are my starting materials: two antique milk glass door knobs, a wooden dowel, two wall hooks, and silver paint. Not pictured are store bought curtain clip rings, Liquid Nails, and the curtain, which is actually a tablecloth.

I painted the dowel. Then I put the curtain rings on the dowel. I used Liquid Nails to glue the dowel into the two antique milkglass doorknobs, which conveniently I bought without the rods that attach them to the door mechanism. The only problem with the way I created this curtain rod is that the curtain rings are now permanently on the rod, unless I want to break the dowel to remove them.

After everything had dried and cured, I attached the rod to the wall using the wall hooks which simply screw into the drywall and studs. [Wooden dowels come in multiple diameters, so I picked the diameter that best fit into the door knobs. Similarly, I bought wall hooks that best fit snugly around the dowel.]

For the curtain, I used a hand painted piece of fabric that my sister gave me, which I think is from Bali. I am pretty sure it is supposed to be a tablecloth, but it fit my window perfectly, and it was too pretty to never have on display. Below is the finished window treatment that is pretty and VERY unique.