I left West Virginia today, but before leaving, I stopped at Sandstone Falls in New River Gorge National Park to do a little hiking. I also drove to a couple of overlooks of New River and Sandstone Falls.

Category Archives: Travel

New River Gorge National Park

I have been sightseeing and hiking in New River Gorge National Park and surrounding area for several days now. I will be posting the photos in a few different posts. I have taken quite a few photos in the area around the New River Gorge Bridge, so those are what I am posting now.

Exhibition Coal Mine

While visiting New River Gorge National Park, I am in the Beckley area, so I decided to visit the Exhibition Coal Mine. It is a museum dedicated to coal mining including structures that show how people used to live. The main attraction though is an actual coal mine that shut down decades ago that you can tour while on a mine car. It was quite interesting. Our guide was a retired coal miner, and he was able to explain how things worked. You cannot stand up straight in the coal mine. We were seated on a car the whole time, but our guide got out several times, and he had to stoop over. He further explained that with most area, they did not remove the rock above the coal seam. The coal seam was generally only 24 inches high, so miners worked on the ground in a 24 inch high area. The work was obviously grueling.

Signs near entrance to mine. They still have a fire boss check the mine everyday even though they are not mining.

Bridge Walk

I spent today doing more exploring of New River Gorge National Park, but I started the day by walking across a bridge. The walk across the bridge was under the road deck, which is not something a person normally gets to do. Bridge Walk lets you do just that. The New River Gorge Bridge is beautiful with a wonderful design, and walking under the bridge allowed me better appreciate and to take photos of the structure. Walking on the catwalk also allows for photos of the stunning scenery. It was a nice, leisurely walk that just happens to be, at the highest point, 876 feet above the ground, by walking on a two feet wide catwalk while attached the longest continuous safety line in the world.

Nuttallburg

I started exploring New River Gorge National Park today. It is second on my list of things to see in West Virginia after the capitol. The park is really spread out, and there are lots of areas to explore. I did some hiking in the Nuttallburg area today because it features the remains of a coal mining operation, and I love ruins. I hiked from the top to the headhouse. I was originally going to hike down along the trail that somewhat follows the conveyor, but I met some people at the headhouse, who had just hiked up the that trail, and they said do not do it. It is a really difficult trail, and while the park material said as much, somehow their exhausted faces persuaded me more. I then drove to area near the river where the lower part of the mining operation was and hiked around there a little. The area trails are really neat because you can essentially follow the mining operation from the mine entrance to where the coal would have been loaded onto trains.

While the mining operation started in the mine, obviously, the first part you can see is the mine entrance. As I stood in front of the mine, I could feel the air coming out was probably 10 or 20 degrees colder.

The coal cars then went to the headhouse where the coal was dumped and loaded onto the conveyor, which brought the coal all the way down the slope to be transferred to trains.

Headhouse where coal was dumped out of the cars from the mine and onto the conveyor. In the lower right, you can see the start of the conveyor.

The conveyor was essentially a really long conveyor belt, and it was kind of awesome to stand beneath it.

The conveyor ended at the tipple. The tall structure seen on the right was a storage silo for the coal.

The tipple sat on top of train tracks, and the coal was transferred to the trains there.

There are also some remains of coke ovens. These are considered to be the earliest remains of coal operations. Originally the coal converted to coke there.

JQ Dickinson Salt-Works

I visited JQ Dickinson Salt-Works, a small, salt-harvesting facility today, and it was fascinating. I love factory tours, but I don’t think the term factory applies to this place, and it would almost be derogatory to call the salt works a factory. In any event, the process was fascinating, and I am somewhat in awe of how low-tech it is, yet I am amazed how they can produce so much salt. My guide said they will produce about 16,000 pounds of salt this year. There used to be springs in the area that Native Americans knew about as they knew that animals liked to lick the salt from the springs. Salt was produced commercially from the springs when white settlers moved in to the area, but then production ended in the twentieth century. The operation was resumed more recently, and the current well was installed in 2013.

The start of the process is somewhat anticlimactic. The process starts with groundwater that is pumped from an aquifer that is 350 feet deep and contains water from an ancient ocean. The anticlimactic part is that the well is below ground (obviously), and so all you see from the surface is a tripod of sorts marking off the location.

The groundwater is first pumped into storage tanks to allow the iron to settle out from the water.

They have sample jars that show what the water looks like when mixed (right) and then once the iron has settled and comes out of solution (left). My guide said they try to keep the process as environmentally friendly as possible and allow little to nothing go to waste. The iron that settles out is eventually sold for wood staining or for pottery glazes.

After the iron settles out, the water is pumped to one of three greenhouses to concentrate in shallow pools in black-lined tables.

I forgot to ask my guide what the starting salinity of the groundwater is, but in these first greenhouses, it sits for about 24 hours until it reaches a salinity of 15%. In the shallow pools, I could see a few fine salt crystals settling out.

The concentrated water or brine is then pumped to another storage tank and then into another greenhouse. In this greenhouse, the salinity is raised to 25%. This is where large salt crystals are formed. One thing I got confused about is that my guide said the salt was now 25% salinity, but they were clearly salt crystals. Visually it didn’t look like 75% water and 25% salt. I am not sure if I understood correctly what is meant by salinity or if I misunderstood her, or if I am just missing a detail. In any event, the salt was quite pretty.

One of the tables had been cleared of the concentrating salt, and there were buckets of salt crystals ready for final processing.

The salt is then moved to another room where it is dried. After that, a person inspects the salt and removes any impurities with tweezers. The women who were working admitted that it is a really tedious job. I would need a headlamp and magnifying glasses to do the task.

The salt is then ready to be sold. They sell it in three crystal sizes (from finest to coarsest): popcorn, finishing, and grinding. They also mix it with spices, most or all of which are grown locally, to sell as spice salt mixes. The liquid that is left over once the salt settles out is also sold as nigari. Nigari is used to make tofu and cheese, and some people take it as supplement as it is full of minerals. This is part of what my guide said is their goal to not let anything go to waste. Until today, I had never even heard the word nigari, so yet another thing I learned today.

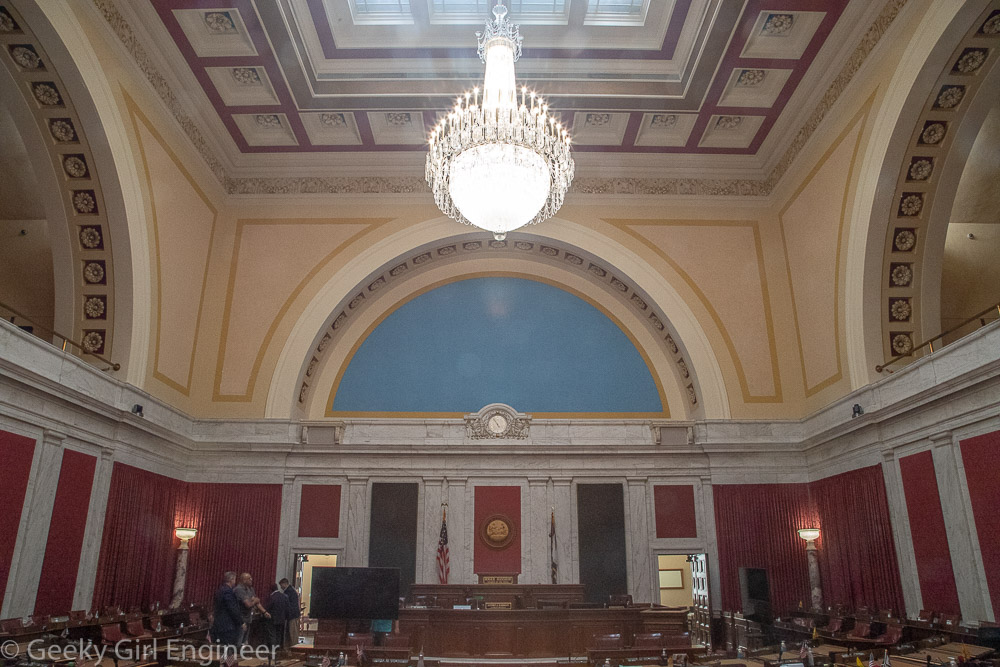

West Virginia State Capitol

I continue in my quest to see all the state capitols. Today, I checked off West Virginia. The current, sixth, and final state capitol is gorgeous but not overly ornate. As just stated, it is the sixth capitol, and the short history of why West Virginia has had that many is one of the reasons why guided tours of capitols are so worth it. The original capitol was in Wheeling from 1858-1870. The Legislature decided to move it to Charleston. According to my guide, Wheeling then stated they would build a wonderful new building and pay for it if they moved the capital back to Wheeling, which they did in 1875. [This sounds like cities competing for sports franchises.] People evidently complained about how far away Wheeling was from the rest of state, and most wanted one more centrally located. Then there was a state wide vote, and Charleston won, and the capital moved back there in 1885. [At this point, you have to wonder if there was niche market for move the capital by steamer business.] Now, I get to the best part of this story, which is about the fourth capitol (and second Charleston capitol). The state had confiscated a whole lot of ammunition, gunpowder, and other material from protestors and/or strikers in coalfields. At least one version of the story I found says the ammunition belonged to police. The capitol was rather large, and evidently they had a bunch of storage space, so with what was thought a good idea at the time, they stored it in the capitol. It caught fire somehow, and the building burned for three days. The fifth capitol was then built really quickly after that, and then they built the current building.

The building is like most capitols with lots of marble and other natural stone. The central dome is really pretty. I like the contrasting colors. The dome and each of the chambers have crystal chandeliers on which the state did not skimp. The senate chamber is red, but the house chamber is more pinkish red. The senate has a small dome with skylight, but the house has larger square skylight. It may have just been the time of day I was there, but the house chamber had more light from the skylight. The exterior of the central dome has lots of real gold, according to my guide, and I think the gold is contrasted nicely with the blue paint.

Kanawha State Forest

After visiting the Coal House, I went to Kanawha State Forest to do a little hiking. The park is pretty, but it had just rained, so hiking was a little difficult in that the trails were rather muddy. It has some nice trails, but unfortunately the map on the website is really not that helpful. One of the trails I wanted to see, the Spotted Salamander Trail, I only found because I asked some people hiking if they knew how to get to it. Still, it was a nice park to visit, and I got some exercise done. My guess is that the park is absolutely gorgeous when the wildflowers are in bloom.

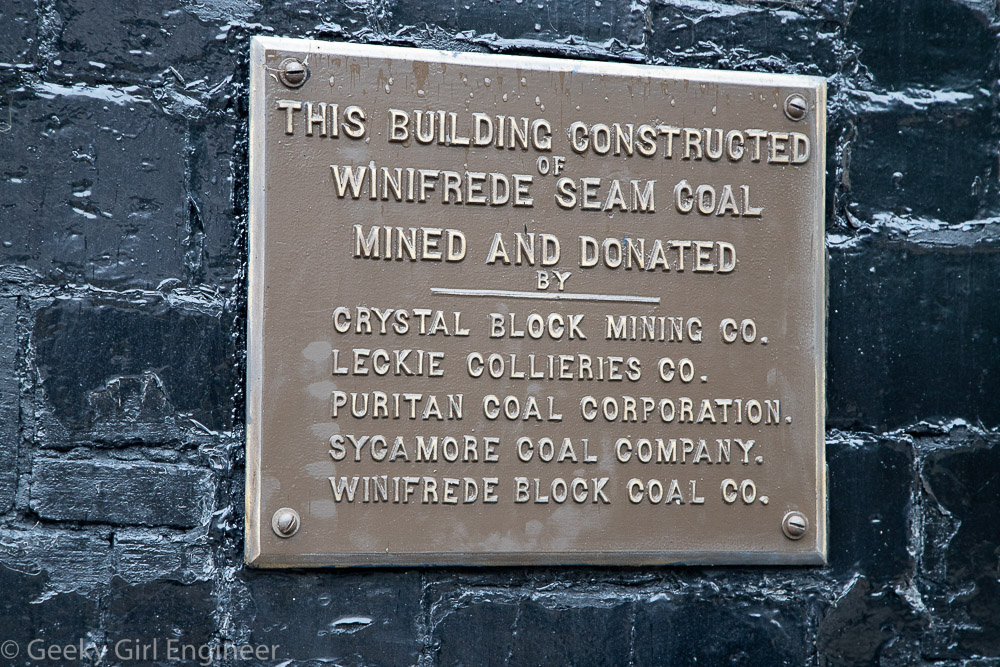

Williamson Coal House

While in Charleston, I found the book “The Essential Way Out in West Virginia” by Jeanne Mozier for sale, and I immediately bought it because this is my kind of book. One of the crazy items in the book, is Coal House, which according to the book is the oldest and largest building made out of coal in West Virginia. It was constructed entirely of coal, and its walls are two feet thick. Incredibly in 2010, the building caught fire, and the interior was gutted, but the coal block exterior was untouched. Supposedly, the exterior is not a fire hazard, which seems to be proven by the fact that it didn’t burn during the fire. However, it is coal, so I am still trying to understand that.

Quite obviously, I had to see this coal house. I drove about three hours roundtrip out of my way to see it, which may be not normal, but it was completely worth it. One detail that I could see in person is that bricks are very shiny. They must be coated with something, probably for weather resistance.

Seneca Rocks

As I continued my West Virginia road trip, after Spruce Knob, I made another stop at Seneca Rocks. They are a beautiful rock formation to see. I didn’t do any hiking, but I just wanted to stop and see them. As I love to see any cool geological formation.